- Up to 50% longer service life thanks to reinforced cage material

- Very good temperature and chemical resistance

- Operating temperature: -100 °C to +150 °C

- Ring material: xirodur® A500

- Cage material: xirodur® F500

- Ball material: glass

xiros® deep groove ball bearing xirodur® A500, heat & chemical specialist, reinforced cage material, glass balls

xirodur® A500 | The specialist with up to 50% longer service life

The material xirodur® A500 is the specialist for high chemical and temperature resistance. In combination with the xirodur® F500 cage, this material combination covers applications with continuous service temperatures from -100 °C to +150 °C, is highly resistant to strong acids and ensures significantly longer maintenance cycles.

Typical appliactions areas:

- Semiconductor industry

- Chemical industry

- Applications with high temperatures

![]()

Tech up:

- New reinforced cage material for up to 50% longer service life compared to A500 cages

- Continuous service temperatures of up to 150 °C

![]()

Cost down:

- Significantly extended maintenance cycles

![]()

Proof:

![]()

Sustainability:

- Environmentally friendly, as no additional lubricants are required

- igus supports the circular economy of plastics and invests in chemical recycling. More at: igus.eu/sustainability

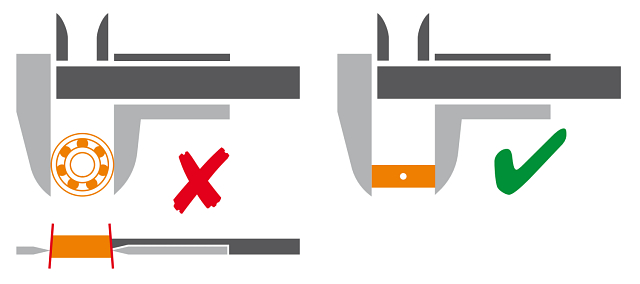

Tolerances and measuring system:

The tolerances for inner and outer diameters depend on the size. These are often approx. ±0.05 mm to the nominal dimension. The bearing rings are usually injection molded and naturally exhibit a certain ovality. For this reason, the caliper gauge is used to measure 90° to the injection point (if present) over the entire width of the bearing. The dimensions and tolerances are designed to meet an easy press fit by hand when using a H7 mounting as well as shaft h6. Additional axial securing by means of a circlip (shaft) and snap ring (housing) is recommended to prevent axial displacement.

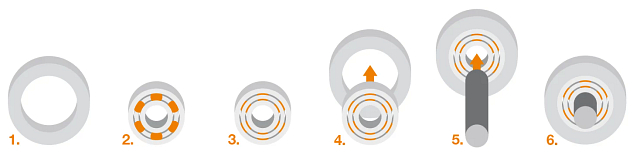

Mounting recommendation:

1. mounting (tolerance H7)

2. front side (balls visible)

3. rear side (cage visible)

4. press in ball bearing with front side first

5. mount shaft (tolerance h6) with chamfer

6. an axial safety device must be provided